On this page:

See more:

On this page:

See more:

In the field of photometric and colorimetric tests and measurements we perform measurements of photometric and colour characteristics of vehicle lighting and road safety devices, as well as others. We also carry out comprehensive tests of lamps and lighting fittings, including those with LED light sources.

BOSMAL performs:

This test (along with the photometric method) can be used to assess the product’s resistance to weather conditions.

The assessment is made by comparing the colour change of the working sample under test with the unexposed sample, using a grey scale.

The grey scale for assessing colour change is used in a 5-grade range (basic scale) and in a 9-grade range, corresponding to half-grade colourfastness indicators.

Standards

In the photo: Byko-spectra chamber (BYK) for visual assessment using a grey scale

We perform colour and colour change measurements using spectrophotometers. Measurements are made at standard measurement geometries: 45/0, d / 8, d / 0 for various types of reflecting, transmitting and light-scattering materials, as well as fluorescent materials.

Test objects

Testing range

Devices

See more: Spectrophotometric colour measurement

Test norms

Test methods consist of determining the mirror gloss of coatings using three geometries: 20°, 60°, 85°

Testing norm

Equipment

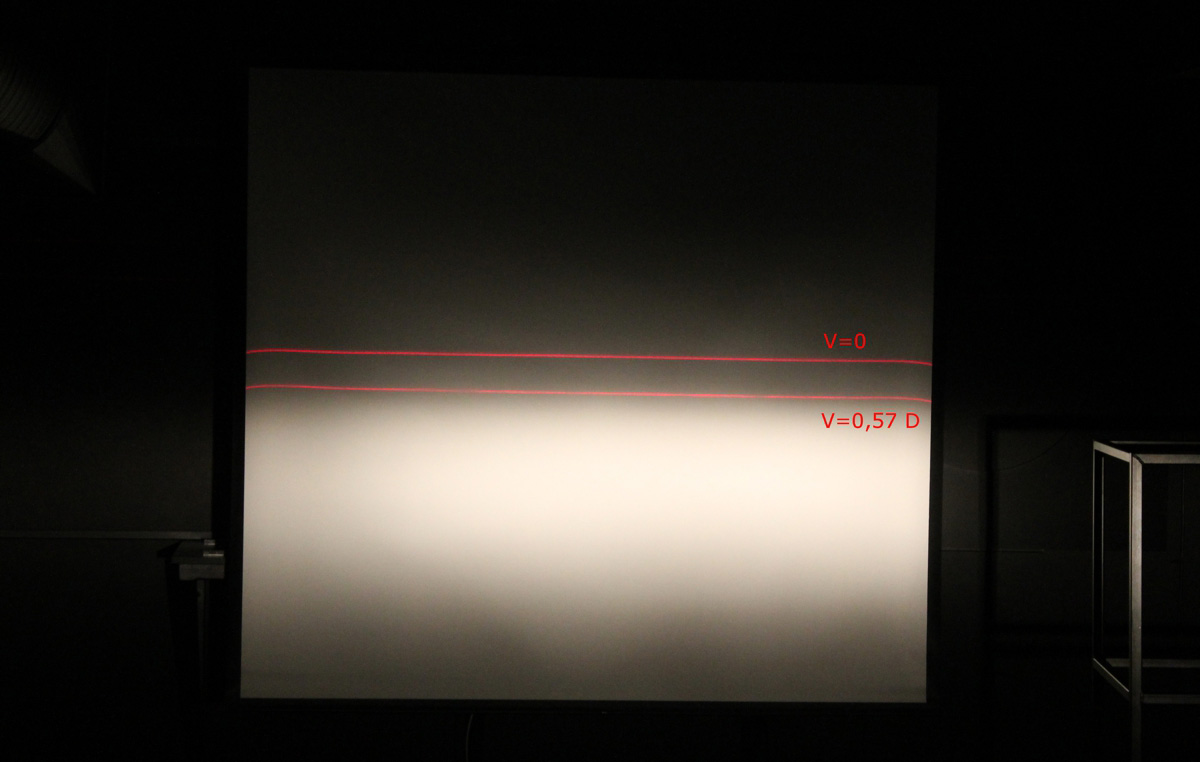

The laboratory offers a wide range of tests in the field of lighting technology. Measurements are carried out in a photometric darkroom with dimensions of 12.5 × 4.5 × 7.5 m. The darkroom is equipped with a photometric tunnel that ensures a measurement distance of 25 m. Measurements are performed under the stable thermal conditions required to obtain reliable and reproducible results.

Quantities measured

Test objects

Measuring and testing equipment

Norms and regulations

Testing range

Photo: Goniophotometer in a photometric darkroom

Equipment

Thermovision, sometimes referred to as thermography, is one of the available methods for thermal inspection of products. It uses the phenomenon of non-contact detection of electromagnetic radiation in the mid-infrared band (wavelengths from approx. 0.9 μm to 14 μm). An infrared camera can therefore register the thermal radiation emitted by physical bodies at temperatures of about -40°C to about 2000°C. Typically, thermal imaging cameras record a range from -20°C to 250°C.

The great advantage of the thermovision method is its lack of invasiveness. In addition, it is possible to conduct temperature measurements at hard-to-reach locations. With the use of thermovision methods, we can quickly diagnose the correct functioning of electrical and electronic components, including industrial automation systems, the uniformity of heating of objects such as machines, furnaces, etc.

BOSMAL uses thermovision measurements for research on (among others):

They are performed, for example, on heat exchangers after the “thermal shock” test.