IP-code. Protection against ingress of solid objects, dust and moisture

IP-code – introduction

IP degree of protection (eng.: ingress protection) – a parameter characterising the enclosure of an electrical device, indicating the level of protection of the user against access to hazardous parts and of the device itself against penetration by external agents.

The IP code consists of the letters “IP”, two characteristic numeral numbers and optionally two letters – an additional letter and a suplementary letter.

The first digit indicates the level of protection the enclosure provides against access to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of solid foreign objects. The second digit indicates the level of protection that the enclosure provides against harmful ingress of water.

IP tests – protection against access to hazardous parts and solid foreign objects

The first letter of the IP code according to the PN-EN 60529 or ISO 20653 standard, for digits from 1 to 4 defines the class of protection against access to hazardous parts and solid foreign objects.

Tests verifying if the enclosure can be assigned a given protection class have been designed so that the degree of protection when using the specific housing is clearly defined. Tests are performed with the use of access probes (spheres, wires and test fingers), applying the force specified in the standard on the test object.

Degree of protection against solid foreign objects

Degree of protection against solid foreign objects provides information on what is the maximum size of objects that can penetrate the enclosure.

| IP degree | Access probe |

| IP1X | Sphere ø 50 mm |

| IP2X | Sphere ø 12.5 mm |

| IP3X | Wire 2.5 mm |

| IP4X | Wire 1 mm |

The condition for a given degree of protection against solid foreign objects is met, when the access probe does not penetrate the enclosure, which could disturb equipment operation.

Degree of protection against access to hazardous parts

Degree of protection against access to hazardous parts provides information on whether the enclosure is protected against the risk of electrocution (by electrical parts), mechanical injuries of the human body (by moving parts), etc.

| IP degree | Access probe |

| IP1X | Sphere ø 50 mm on a handle |

| IP2X | Sphere ø 12.5 mm on a handle / test finger (depending on the standard) |

| IP3X | Wire 2.5 mm on a handle |

| IP4X | Wire 1 mm on a handle |

The access is verified with the use of a system that signals closing of the electrical circuit.

BOSMAL’s tests covering the entire IP protection range

Standards

- PN-EN 60529

- DIN 40050-9

- ISO 20653

All our IP testing methods are certified (AB 128 accreditation).

IP tests (dust resistance)

Test benches

- chambers with vertical circulation of dust-air mixture of volumes 1 m3 and 0.3 m3.

Characteristics of the dust chamber of volume 1 m3

- dimensions of the chamber workspace: (1000 x 1000 x 1000) mm,

- the ability to perform tests at ambient temperature and at elevated temperature (up to 100°C),

- the ability to perform tests at negative pressure,

- access opening with a diameter of 80 mm, enabling the routing of power cables and vacuum hoses to the test objects inside the chamber,

- possibility of coupling the chamber with an external drive system, e.g. in the case of tests on alternators.

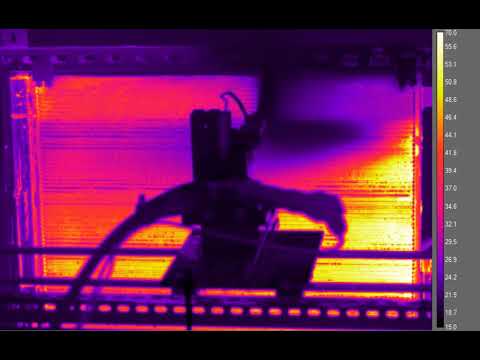

Example test in dust chamber – alternator durability testing

IP tests (resistance to water)

Testing performed

- resistance to dripping water (IPX1, IPX2)

- resistance to rain (IPX3, IPX4) using a tube with oscillating movement,

- resistance to spurts of water (IPX5, IPX6, IPX6K),

- immersion (IPX7, IPX8),

- resistance to high-pressure washing (IPX9, IPX9K).

In the photo: Testing an electric motor for IPX6K protection class

Rain testing stands

Other water resistance tests

Testing the resistance of products to wading through water

Example: testing an electric vehicle cooling fan

Damp resistance tests

Technical parameters

- Water flow rate: up to 40 l/min

- Rotational speed: controlled

Flow tubes in accordance with:

- JIS D 0203

- DIN 40050 part 9

- EN 60529

Resistance to high-pressure washing test

Technical parameters

- Water flow rate: up to 16 l/min

- Water pressure: up to 100 bar

- Water temperature: up to 100°C

- Flow stream: flat (25° to 40°)

- Element mounted in a fixed position, or with the possibility of rotating in a single plane through 360°

High Pressure Cleaning with Thermal Shock

Technical parameters

- test object temperature around 80°C (oil),

- water temperature to 14°C,

- water pressure 82 bars

Standards

- DIN 40050-9

- ISO 12103-1

- ISO 20653

- JIS D 0203

- PN-EN 60529

- VW 80000 (M-03)

Back

to top